Researchers from A*STAR’s NanoBio Lab (NBL) have designed a semi-solid electrolyte for lithium-sulfur batteries that improves their safety without compromising their performance 1. This promising breakthrough paves the way for lithium-sulfur batteries to be used as efficient power solutions across diverse electronic and energy storage applications.

Safety is an important issue hindering the use of lithium batteries by industry, due to their highly flammable liquid organic electrolytes that leak easily, and their reliance on thermally and mechanically unstable electrode separators. While solid-state electrolytes have shown potential for improving the safety profile of lithium batteries, their poor electrode/electrolyte contact and limited ionic conductivity have resulted in major conductivity bottlenecks and low performance.

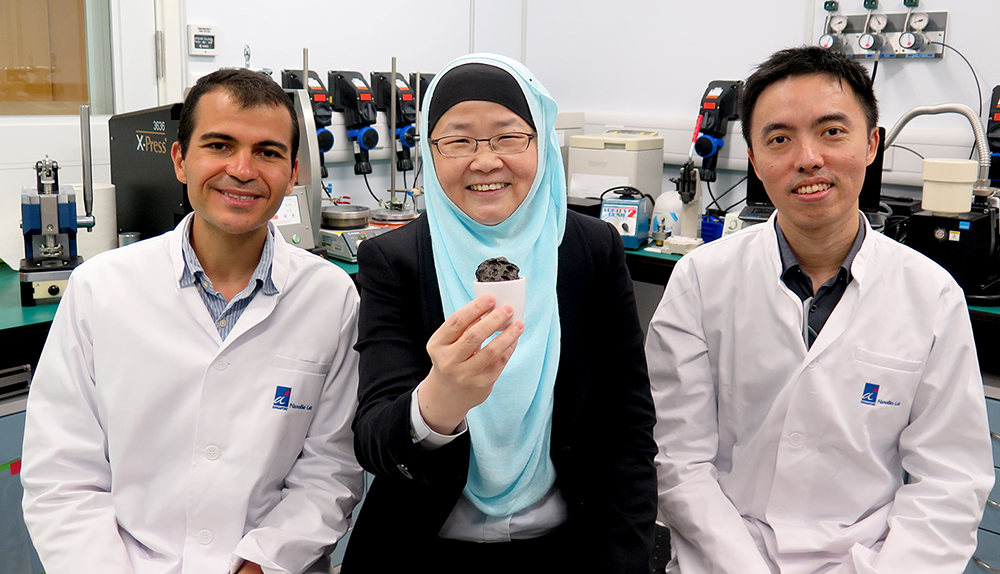

Prof. Jackie Y. Ying, who heads the NBL research team shared, “Hybrid quasi-solid electrolytes comprising both liquid and solid components have emerged as a practical compromise to obtain safer batteries while maintaining good performance. However, the high resistance of the solid component has thus far limited the performance of such batteries. To overcome this, we have reengineered the microstructure of the solid component. Our solution eliminates electrolyte leakage, and is thermally and mechanically stable.”

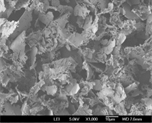

The NBL research team designed a hybrid quasi-solid electrolyte, which comprises a liquid-infused porous membrane made of Li7La3Zr2O12 (LLZO) sheets. The team also developed a novel method of fabricating the LLZO sheets used to construct the framework for the electrolyte. They named this one-step process for producing a 3D-sheet framework the ‘cupcake’ method.

LLZO was chosen for its high ionic conductivity, and good chemical and electrochemical stability. The electrolyte’s non-rigid structure allows it to maintain very good contact with electrodes and prevents it from cracking during handling and battery assembly. This results in safer batteries with better performance. NBL’s semi-solid electrolyte is also stable over a wide voltage range, allowing it to be used with different lithium battery electrode materials including high-voltage cathodes.

A lithium-sulfur battery made using NBL’s novel electrolyte showed high capacity, fast charge/discharge capability, and interesting polysulfide shuttling control 2 that stabilized the battery’s performance. In tests, the novel electrolyte achieved remarkable rate capability (~515 and ~340 mAh/g at 1 and 2C, respectively) at 1.5 mg/cm2 loading density. This is among the highest known performance achieved by lithium-sulfur hybrid quasi-solid batteries.

Prof. Ying said, “Our 3D sheet-based framework was found to be crucial for optimal battery performance. Moreover, our system demonstrated outstanding stability under extreme temperatures. These results illustrate the excellent potential of our sheet-based structure as a framework for other semi-solid lithium batteries.”

The NBL team is developing novel lithium-ion, lithium-sulfur and lithium solid-state batteries towards commercialization.

One-Step ‘Cupcake’ Synthesis Method

Metal precursors and sucrose are dissolved in water and placed in a pre-programmed furnace.

Inside the furnace:

- The solution is heated to form a brown ‘cupcake’.

- The ‘cupcake’ is then heated at high temperature to form sheets (image).

A. A. AbdelHamid, J. L. Cheong and J. Y. Ying, “Li7La3Zr2O12 Sheet-Based Framework for High-Performance Lithium-Sulfur Hybrid Quasi-Solid Battery,” Nano Energy, 71 (2020) 104633.